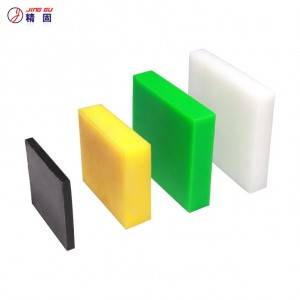

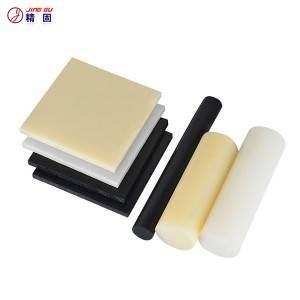

Well-designed China Multi-Color Engravable Anti-UV Dual Color High Density Polyethylene Sheets

Our solutions are broadly identified and trusted by buyers and might fulfill continuously changing economic and social wants of Well-designed China Multi-Color Engravable Anti-UV Dual Color High Density Polyethylene Sheets, We warmly welcome enterprise partners from all walks of daily life, be expecting to establish helpful and cooperative enterprise contact along with you and accomplish a win-win aim.

Our solutions are broadly identified and trusted by buyers and might fulfill continuously changing economic and social wants of China High Density Polyethylene Sheet, Polyethylene Sheets, Our company always concentrate on the development of the international market. We have now a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

Product Description

High-density polyethylene (HDPE) is a kind of high-crystalinity, non-polar thermoplastic resin. It’s a milky white translucent waxy solid with good chemical stability, resistant to most acid, alkali and organic solutions, good insulation, easy to weld.

|

JING GU PRODUCT PHYSICAL PROPERTIES |

||||

|

Property |

Items |

Test method |

Unit |

JING GU HDPE |

|

Mechanical property |

Tensile strength |

ISO 527-1、2 |

Mpa |

32 |

|

Bending strength |

ISO 178 |

Mpa |

|

|

|

Bending tensile stress |

ISO 527 |

Mpa |

30 |

|

|

Stretching strain at break |

ISO 527 |

% |

|

|

|

Tensile modules of elasticity |

ISO 527 |

Mpa |

900 |

|

|

Compressive stress under 1% and 2% normal strain |

ISO 604 |

Mpa |

3/- |

|

|

Pendulum impact test |

ISO 179/1eA |

kj/m2 |

|

|

|

Rockwell hardness |

|

HR |

|

|

|

Physical property |

Density |

ISO 1183 |

g/cm3 |

0.96 |

|

Water absorption (23℃ water soak for 24 hours) |

ISO 62 |

% |

|

|

|

Coefficients of linear thermal expansion (23-100℃ average value) |

|

m/(m.k) |

155×10-6 |

|

|

Flammability (UL) |

UL94 |

|

HB |

|

|

Heat resistance |

Melting point |

|

℃ |

130 |

|

Temperature resistance (continuous) |

|

℃ |

90 |

|

|

Temperature resistance (short time) |

|

℃ |

110 |

|

|

Insulating property |

Dielectric strength |

ISO 60243 |

kv/mm |

>50 |

|

Volume resistance |

ISO 60093 |

Ω·cm |

≥1O15 |

|

|

Surface resistance |

ISO 60093 |

Ω |

≥1O16 |

|

|

Relative permittivity -100HZ/1MHZ |

ISO 60250 |

|

2.4/– |

|

|

Chemical property |

Acid resistance |

|

|

+ |

|

Alkali resistance |

|

|

+ |

|

|

Carbonation resistance |

|

|

+ |

|

|

Aromatic compounds resistance |

|

|

0 |

|

|

Ketone resistance |

|

|

+ |

|

|

Other |

Adhesion |

|

|

0 |

|

Friction coefficient |

|

|

0.3 |

|

|

Food contact |

|

|

+ |

|

|

Remark |

1.Above data is only for reference.It may vary according to different processing method and sample. 2.These data can’t be simply transferred to the finished parts.The applicability of materials for specific applications should be tested by the processor and user. 3.These technical parameters are used as a help.They do not represent a promise of performance. 4.Above specification “+” represents resistant, “-” represents resistless, “0″ represents it depends. |

|||

Properties

1.Excellent low temperature resistance, minimum operating temperature up to -70 degrees Celsius

2.Good chemical stability, resistant to most acid and alkali

3.Low water absorption, excellent electrical insulation

4.Non-toxic and environmentally friendly, food contact material

5.Poor heat resistance, poor aging resistance

Application

Widely used in the chemical, mechanical, electric power, packaging, food and other industries to manufacture wear resistant and impact resistant mechanical parts, such as drinking water pipes, hot water pipes, transportation containers, pump valve parts, medical equipment, seals, sliding profiles, etc.