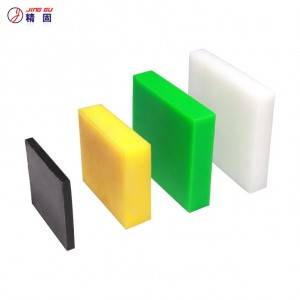

OEM/ODM Factory China Color UHMWPE HDPE Plastic Product PP Sheets/ PE Engineering Plastic Board

“Control the standard by the details, show the power by quality”. Our business has strived to establish a highly efficient and stable team staff and explored an effective good quality regulate course of action for OEM/ODM Factory China Color UHMWPE HDPE Plastic Product PP Sheets/ PE Engineering Plastic Board, High quality, timely service and Aggressive rate, all earn us a excellent fame in xxx field despite the international intense competition.

“Control the standard by the details, show the power by quality”. Our business has strived to establish a highly efficient and stable team staff and explored an effective good quality regulate course of action for China Plastic Sheets, Plastic Board, We now have a good reputation for stable quality products, well received by customers at home and abroad. Our company would be guided by the idea of “Standing in Domestic Markets, Walking into International Markets”. We sincerely hope that we could do business with customers both at home and abroad. We expect sincere cooperation and common development!

Product Description

Polypropylene also known as PP, is a kind of translucent milky white linear polymer with high density, no side chain and high crystallinity. It is obtained by polymerization of propylene and it’s one of the lightest varieties of all plastics.

|

JING GU PRODUCT PHYSICAL PROPERTIES |

||||

|

Property |

Items |

Test method |

Unit |

JING GU PP |

|

Mechanical property |

Tensile strength |

ISO 527-1、2 |

Mpa |

30 |

|

Bending strength |

ISO 178 |

Mpa |

|

|

|

Bending tensile stress |

ISO 527 |

Mpa |

|

|

|

Stretching strain at break |

ISO 527 |

% |

>50 |

|

|

Tensile modules of elasticity |

ISO 527 |

Mpa |

1450 |

|

|

Compressive stress under 1% and 2% normal strain |

ISO 604 |

Mpa |

4/- |

|

|

Pendulum impact test |

ISO 179/1eA |

kj/m2 |

5 |

|

|

Rockwell hardness |

|

HR |

R85 |

|

|

Physical property |

Density |

ISO 1183 |

g/cm3 |

0.91 |

|

Water absorption (23℃ water soak for 24 hours) |

ISO 62 |

% |

|

|

|

Coefficients of linear thermal expansion (23-100℃ average value) |

|

m/(m.k) |

150×10-6 |

|

|

Flammability (UL) |

UL94 |

|

HB |

|

|

Heat resistance |

Melting point |

|

℃ |

170 |

|

Temperature resistance (continuous) |

|

℃ |

95 |

|

|

Temperature resistance (short time) |

|

℃ |

115 |

|

|

Insulating property |

Dielectric strength |

ISO 60243 |

kv/mm |

>40 |

|

Volume resistance |

ISO 60093 |

Ω·cm |

≥1O14 |

|

|

Surface resistance |

ISO 60093 |

Ω |

≥1O13 |

|

|

Relative permittivity -100HZ/1MHZ |

ISO 60250 |

|

2.3/– |

|

|

Chemical property |

Acid resistance |

|

|

+ |

|

Alkali resistance |

|

|

+ |

|

|

Carbonation resistance |

|

|

+ |

|

|

Aromatic compounds resistance |

|

|

- |

|

|

Ketone resistance |

|

|

+ |

|

|

Other |

Adhesion |

|

|

0 |

|

Friction coefficient |

|

|

0.3 |

|

|

Food contact |

|

|

+ |

|

|

Remark |

1.Above data is only for reference.It may vary according to different processing method and sample. 2.These data can’t be simply transferred to the finished parts.The applicability of materials for specific applications should be tested by the processor and user. 3.These technical parameters are used as a help.They do not represent a promise of performance. 4.Above specification “+” represents resistant, “-” represents resistless, “0″ represents it depends. |

|||

Properties

1. Low density with good weldability

2. Heat resistance

3. Good corrosion resistance, resistant to strong acids and strong base

4. Non-toxic, suitable for food hygiene requirements, can be used for food utensils

5. Easy to accumulate static electricity

6. Easy to age with copper contact

7. Poor weather resistance, sensitive to ultraviolet light, easy to age

8. Poor cold resistance, low low temperature impact strength

Application

Suitable for making general mechanical parts, corrosion resistant and insulating parts, drinking water or sewage pipe, spraying carrier, corrosion resistant trough, acid and alkali resistant industry, waste water, exhaust gas discharge equipment, food machinery, chopping board, rolling pin, plating equipment and etc.