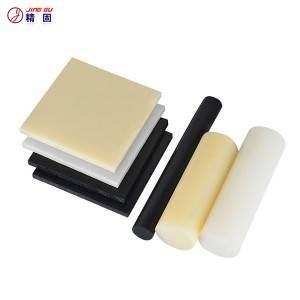

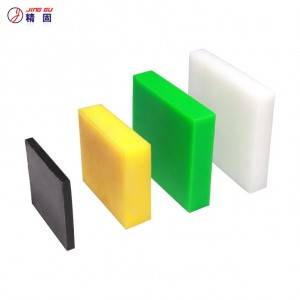

High reputation China ABS Acrylic Kt PVC PS Display Board

To meet the customers’ over-expected satisfaction , we have our strong team to provide our best overall service which includes marketing, sales, designing, production, quality controlling, packing, warehousing and logistics for High reputation China ABS Acrylic Kt PVC PS Display Board, We sincerely welcome friends to negotiate business and start cooperation with us. We hope to join hands with friends in different industries to create a brilliant future.

To meet the customers’ over-expected satisfaction , we have our strong team to provide our best overall service which includes marketing, sales, designing, production, quality controlling, packing, warehousing and logistics for Acrylic Board, China PS Display Board, Selling our solutions causes no risks and brings high returns to your company instead. It is our consistent pursuit to create value for clients. Our company is looking for agents sincerely. What are you waiting for? Come and join us. Now or never.

Product Description

Acrylonitrile butadiene styrene copolymer (ABS) is an opaque beige thermoplastic resin which is copolymerized by acrylonitrile, butadiene and styrene.

|

JING GU PRODUCT PHYSICAL PROPERTIES |

||||

|

Property |

Items |

Test method |

Unit |

JING GU ABS |

|

Mechanical property |

Tensile strength |

ISO 527-1、2 |

Mpa |

45 |

|

Bending strength |

ISO 178 |

Mpa |

63 |

|

|

Bending tensile stress |

ISO 527 |

Mpa |

70/- |

|

|

Stretching strain at break |

ISO 527 |

% |

|

|

|

Tensile modules of elasticity |

ISO 527 |

Mpa |

2100 |

|

|

Compressive stress under 1% and 2% normal strain |

ISO 604 |

Mpa |

17/- |

|

|

Pendulum impact test |

ISO 179/1eA |

kj/m2 |

|

|

|

Rockwell hardness |

|

HR |

R109 |

|

|

Physical property |

Density |

ISO 1183 |

g/cm3 |

1.1 |

|

Water absorption (23℃ water soak for 24 hours) |

ISO 62 |

% |

|

|

|

Coefficients of linear thermal expansion (23-100℃ average value) |

|

m/(m.k) |

100×10-6 |

|

|

Flammability (UL) |

UL94 |

|

HB |

|

|

Heat resistance |

Melting point |

|

℃ |

170 |

|

Temperature resistance (continuous) |

|

℃ |

70 |

|

|

Temperature resistance (short time) |

|

℃ |

85 |

|

|

Insulating property |

Dielectric strength |

ISO 60243 |

kv/mm |

>20 |

|

Volume resistance |

ISO 60093 |

Ω·cm |

1O14 |

|

|

Surface resistance |

ISO 60093 |

Ω |

≥1O13 |

|

|

Relative permittivity -100HZ/1MHZ |

ISO 60250 |

|

|

|

|

Chemical property |

Acid resistance |

|

|

+ |

|

Alkali resistance |

|

|

0 |

|

|

Carbonation resistance |

|

|

+ |

|

|

Aromatic compounds resistance |

|

|

- |

|

|

Ketone resistance |

|

|

- |

|

|

Other |

Adhesion |

|

|

+ |

|

Friction coefficient |

|

|

0.5 |

|

|

Food contact |

|

|

- |

|

|

Remark |

1.Above data is only for reference.It may vary according to different processing method and sample. 2.These data can’t be simply transferred to the finished parts.The applicability of materials for specific applications should be tested by the processor and user. 3.These technical parameters are used as a help.They do not represent a promise of performance. 4.Above specification “+” represents resistant, “-” represents resistless, “0″ represents it depends. |

|||

Properties

1.Good impact strength and heat resistance

2.Excellent chemical resistance and electrical insulation properties

3.Low water absorption, easy dyeing, good electroplating and corrosion resistance

4.Low bending strength and compressive strength

5.Poor weather resistance, easy to degrade under the action of ultraviolet light

Application

Widely used in automotive, electronics, electrical and other product models, mechanical parts, chemical equipment, etc.