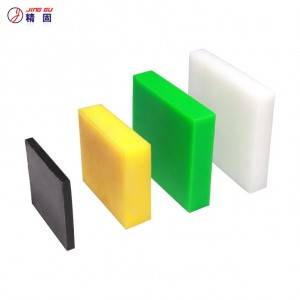

Excellent quality China Engineering Mc Nylon Plastic Sheet, Cast Nylon Sheet with RoHS

Our organization aims to operating faithfully, serving to all of our consumers , and working in new technology and new machine continually for Excellent quality China Engineering Mc Nylon Plastic Sheet, Cast Nylon Sheet with RoHS, We put sincere and health as the primary responsibility. We have a qualified international trade group which graduated from America. We’re your next business partner.

Our organization aims to operating faithfully, serving to all of our consumers , and working in new technology and new machine continually for China Cast Nylon Sheet, PA6g Sheet, Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. Now we have tightened inspection for quality of product.

Product Description

Extruded nylon is the most important engineering plastics. The product is widely used in almost every fields and it’s the most widely used plastic of the five engineering plastics. There are many types of nylon, including nylon 6, nylon 66, nylon 11, nylon 12, nylon 46, nylon 610, etc. However, nylon 6 and nylon 66 are the most important varieties and the output of nylon 6 and nylon 66 are dominant.

PA6 is a translucent or opaque milky crystalline polymer which is made of polymerization of caprolactam monomer at high temperature. The material has the most superior comprehensive performance including mechanical strength, stiffness, toughness, mechanical shock resistance and wear resistance. All these properties combined with good electrical insulation and chemical resistance make PA6 a general purpose grade material for manufacture of mechanical components and maintainable parts.

|

JING GU PRODUCT PHYSICAL PROPERTIES |

||||

|

Property |

Items |

Test method |

Unit |

JING GU PA6 |

|

Mechanical property |

Tensile strength |

ISO 527-1、2 |

Mpa |

78 |

|

Bending strength |

ISO 178 |

Mpa |

100 |

|

|

Bending tensile stress |

ISO 527 |

Mpa |

76/- |

|

|

Stretching strain at break |

ISO 527 |

% |

>50 |

|

|

Tensile modules of elasticity |

ISO 527 |

Mpa |

3250 |

|

|

Compressive stress under 1% and 2% normal strain |

ISO 604 |

Mpa |

24/46 |

|

|

Pendulum impact test |

ISO 179/1eA |

kj/m2 |

5.5 |

|

|

Rockwell hardness |

|

HR |

R106 |

|

|

Physical property |

Density |

ISO 1183 |

g/cm3 |

1.14 |

|

Water absorption (23℃ water soak for 24 hours) |

ISO 62 |

% |

1.28 |

|

|

Coefficients of linear thermal expansion (23-100℃ average value) |

|

m/(m.k) |

90×10-6 |

|

|

Flammability (UL) |

UL94 |

|

HB |

|

|

Heat resistance |

Melting point |

|

℃ |

220 |

|

Temperature resistance (continuous) |

|

℃ |

80 |

|

|

Temperature resistance (short time) |

|

℃ |

120 |

|

|

Insulating property |

Dielectric strength |

ISO 60243 |

kv/mm |

25 |

|

Volume resistance |

ISO 60093 |

Ω·cm |

1O14 |

|

|

Surface resistance |

ISO 60093 |

Ω |

1O13 |

|

|

Relative permittivity -100HZ/1MHZ |

ISO 60250 |

|

3.9/3.3 |

|

|

Chemical property |

Acid resistance |

|

|

﹢/0 |

|

Alkali resistance |

|

|

+ |

|

|

Carbonation resistance |

|

|

﹢/0 |

|

|

Aromatic compounds resistance |

|

|

﹢/0 |

|

|

Ketone resistance |

|

|

+ |

|

|

Other |

Adhesion |

|

|

+ |

|

Friction coefficient |

|

|

0.36 |

|

|

Food contact |

|

|

+ |

|

|

Remark |

1.Above data is only for reference.It may vary according to different processing method and sample. 2.These data can’t be simply transferred to the finished parts.The applicability of materials for specific applications should be tested by the processor and user. 3.These technical parameters are used as a help.They do not represent a promise of performance. 4.Above specification “+” represents resistant, “-” represents resistless, “0″ represents it depends. |

|||

Properties

1. High mechanical strength, good toughness, high tensile and compressive strength

2. Excellent fatigue resistance

3. Smooth surface with low friction coefficient, good wear resistance

4. Corrosion resistance, resistant to alkali, most salt solutions, weak acids, engine oil and gasoline

5. Non-toxic, inert to bioerosion, good antibacterial and antiviral ability

6. Heat resistance, wide temperature range for using, can be long-term used at -40℃ to 100℃

7. Excellent electrical performance, good electrical insulation

8. Not resistant to strong acids and oxidants

9. Poor light resistance and dye ability

Application

Widely used in machinery, automotive, electrical, chemical, aviation, marine and other fields, replacing copper and wearing parts of other metal materials such as bearing, shaft sleeve, bushing, gear, rack, pulley, slider, nut, screw, piston ring, chain wheel, belt pulley, pump impeller, valve seat and so on.