Discount Price China 6061 T6 5 Bar PE Aluminum Checkered Plate

Bear “Customer first, Excellent first” in mind, we work closely with our shoppers and supply them with efficient and specialist services for Discount Price China 6061 T6 5 Bar PE Aluminum Checkered Plate, We warmly welcome domestic and overseas customers send out inquiry to us ,we’ve 24hours doing work staff! Anytime anywhere we are still here to generally be your partner.

Bear “Customer first, Excellent first” in mind, we work closely with our shoppers and supply them with efficient and specialist services for China Aluminum Checkered Sheet, Polished Aluminum Sheet, As a way to use the resource on the expanding info in international trade, we welcome prospects from everywhere on the web and offline. In spite on the high quality objects we offer you, effective and satisfying consultation service is supplied by our qualified after-sale service group. Item lists and in depth parameters and any other info weil be sent to you timely for the inquiries. So you should make contact with us by sending us emails or call us when you’ve got any questions about our organization. ou could also get our address information from our site and come to our enterprise. We get a field survey of our merchandise. We’re confident that we are going to share mutual accomplishment and create solid co-operation relations with our companions within this market place. We’re seeking forward for your inquiries.

Product Description

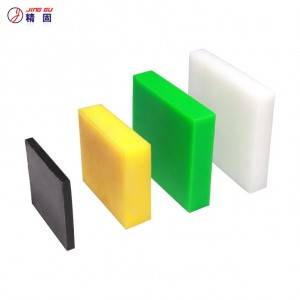

High-density polyethylene (HDPE) is a kind of high-crystalinity, non-polar thermoplastic resin. It’s a milky white translucent waxy solid with good chemical stability, resistant to most acid, alkali and organic solutions, good insulation, easy to weld.

|

JING GU PRODUCT PHYSICAL PROPERTIES |

||||

|

Property |

Items |

Test method |

Unit |

JING GU HDPE |

|

Mechanical property |

Tensile strength |

ISO 527-1、2 |

Mpa |

32 |

|

Bending strength |

ISO 178 |

Mpa |

|

|

|

Bending tensile stress |

ISO 527 |

Mpa |

30 |

|

|

Stretching strain at break |

ISO 527 |

% |

|

|

|

Tensile modules of elasticity |

ISO 527 |

Mpa |

900 |

|

|

Compressive stress under 1% and 2% normal strain |

ISO 604 |

Mpa |

3/- |

|

|

Pendulum impact test |

ISO 179/1eA |

kj/m2 |

|

|

|

Rockwell hardness |

|

HR |

|

|

|

Physical property |

Density |

ISO 1183 |

g/cm3 |

0.96 |

|

Water absorption (23℃ water soak for 24 hours) |

ISO 62 |

% |

|

|

|

Coefficients of linear thermal expansion (23-100℃ average value) |

|

m/(m.k) |

155×10-6 |

|

|

Flammability (UL) |

UL94 |

|

HB |

|

|

Heat resistance |

Melting point |

|

℃ |

130 |

|

Temperature resistance (continuous) |

|

℃ |

90 |

|

|

Temperature resistance (short time) |

|

℃ |

110 |

|

|

Insulating property |

Dielectric strength |

ISO 60243 |

kv/mm |

>50 |

|

Volume resistance |

ISO 60093 |

Ω·cm |

≥1O15 |

|

|

Surface resistance |

ISO 60093 |

Ω |

≥1O16 |

|

|

Relative permittivity -100HZ/1MHZ |

ISO 60250 |

|

2.4/– |

|

|

Chemical property |

Acid resistance |

|

|

+ |

|

Alkali resistance |

|

|

+ |

|

|

Carbonation resistance |

|

|

+ |

|

|

Aromatic compounds resistance |

|

|

0 |

|

|

Ketone resistance |

|

|

+ |

|

|

Other |

Adhesion |

|

|

0 |

|

Friction coefficient |

|

|

0.3 |

|

|

Food contact |

|

|

+ |

|

|

Remark |

1.Above data is only for reference.It may vary according to different processing method and sample. 2.These data can’t be simply transferred to the finished parts.The applicability of materials for specific applications should be tested by the processor and user. 3.These technical parameters are used as a help.They do not represent a promise of performance. 4.Above specification “+” represents resistant, “-” represents resistless, “0″ represents it depends. |

|||

Properties

1.Excellent low temperature resistance, minimum operating temperature up to -70 degrees Celsius

2.Good chemical stability, resistant to most acid and alkali

3.Low water absorption, excellent electrical insulation

4.Non-toxic and environmentally friendly, food contact material

5.Poor heat resistance, poor aging resistance

Application

Widely used in the chemical, mechanical, electric power, packaging, food and other industries to manufacture wear resistant and impact resistant mechanical parts, such as drinking water pipes, hot water pipes, transportation containers, pump valve parts, medical equipment, seals, sliding profiles, etc.